-

I-SIC/I-Silicon carbide Isihluzo se-Ceramic Foam yokuhluza isinyithi esinyibilikisiweyo esingeyo-ferro

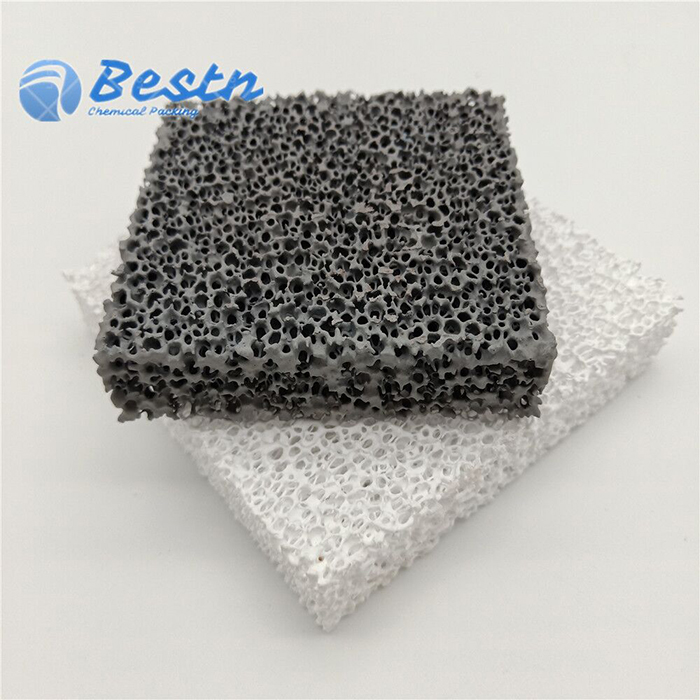

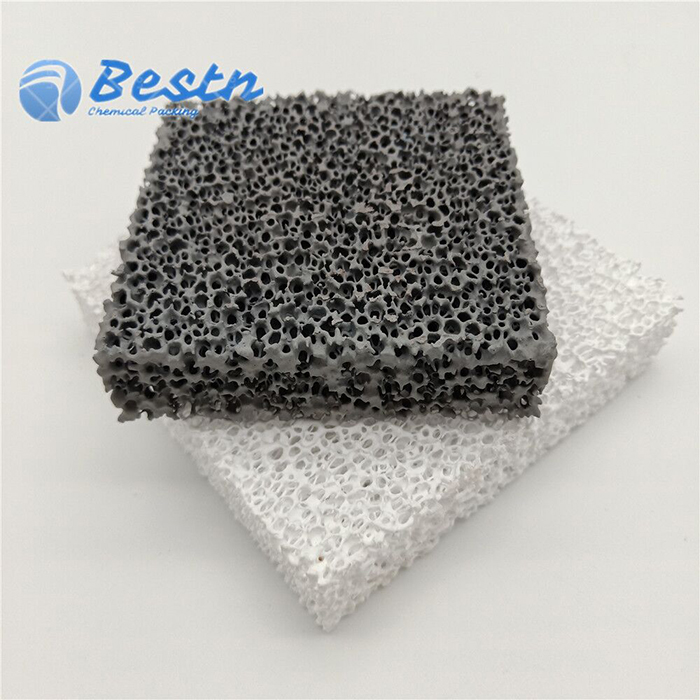

Izihluzi ze-Silicon Carbide zeCeramic Foam ikakhulu zokuhluza isinyithi esityhidiweyo kunye neealloys ezingenayo i-ferrous.Ngokumelana kwabo okugqwesileyo ekuhlaseleni kunye nokugqwala kulwelo lwentsimbi enyibilikisiweyo, banokususa ngokufanelekileyo ukubandakanywa, ukunciphisa igesi evalelweyo kwintsimbi engamanzi kwaye banikeze ukuhamba kwe-laminar, kwaye ke intsimbi ehluziweyo icocekile kakhulu.Isinyithi esicocekileyo siphumela kwi-castings ephezulu, i-scrap encinci, kunye neziphene ezimbalwa zokubandakanywa, zonke ezinegalelo kwinzuzo ephantsi.Izihluzi ze-SiC Ceramic Foam zifumaneka kuzo zonke imilinganiselo esemgangathweni kunye nobukhulu obahlukeneyo.Iiporosities eziqhelekileyo ziyiPPI 10, 20 kunye ne-30;iiporosity eziphezulu ziyafumaneka xa uceliwe.Izihluzi ezenziwe ngokwesiqhelo zokusika ukuya kubungakanani nazo ziyenzeka.

-

Isihluzo se-Alumina yeCeramic yogwebu lokucoca i-aluminiyam etyhidiweyo ye-alloy filtration

Isihluzo se-aluminiyam kunye ne-aluminiyam ye-aluminiyam isetyenziselwa ukuhluza i-aluminiyam kunye ne-alloys kwi-Foundries kunye nezindlu ezityhidiweyo.Ngokuxhathisa ukothuka kwe-thermal kunye nokuxhathisa ukubola kwi-aluminium etyhidiweyo, banokuphelisa ngokufanelekileyo ukubandakanywa, ukunciphisa igesi ebanjwe kunye nokubonelela ukuhamba kwe-laminar, kwaye ke isinyithi esihluziweyo sicocekile kakhulu.Isinyithi esicocekileyo siphumela kwi-castings ephezulu, i-scrap encinci, kunye neziphene ezimbalwa zokubandakanywa, zonke ezinegalelo kwinzuzo ephantsi.

-

i-zirconia iphosa i-ceramic foam filter

I-Zirconia foam i-ceramic filter yenziwe nge-zirconia ephezulu kunye nococeko oluphezulu, isebenzisa ifomula ekhethekileyo kunye neteknoloji yokukhusela indalo.Inokwakheka komnatha olinganayo onamacala amathathu, amandla aphezulu, ukuthungwa okuzinzileyo, akukho kwehla kwe-slag, ukumelana nobushushu obuphezulu, kunye ne-thermal shock resistance ect performance egqwesileyo.Ilungele ukuhlanjululwa kunye nokuhluzwa kwensimbi engenasici, i-carbon steel, i-copper castings kunye nezinye izisombululo eziphezulu ze-alloy ezingaphantsi kwe-1700C.Ngaba ukucoca i-non-metal slag inclusions kunye ne-slags encinci njenge-micrometers, okwenza umphezulu we-casting castings ube lula kunye nokunciphisa ilahleko yomatshini;isihluzi singenza intsimbi enyibilikisiweyo igcwalise umngxuma ngokulinganayo ngakumbi, kwaye isinyithi esinyibilikisiweyo sinesiphithiphithi esiphezulu ngexesha lokugalela ukuthambekela, isiphithiphithi esigeleza kwisakhiwo sepore esine-dimensional-dimensional iguqulwa ibe yimpompozo ezinzileyo yelaminar.Ukuhamba kwe-Laminar kuzalisa i-cavity ngcono, okunciphisa impembelelo ye-corrosion yesisombululo sesinyithi kwindawo yokuphosa, kwaye kunciphisa kakhulu izinga lokwaliwa, ukunciphisa iindleko zemveliso, kunye nokuphucula imveliso yabasebenzi.