Isihluzo se-Alumina yeCeramic yogwebu lokucoca i-aluminiyam etyhidiweyo ye-alloy filtration

Isihluzo se-Alumina yeCeramic yogwebu lokucoca i-aluminiyam etyhidiweyo ye-alloy filtration

| Ubungakanani (mm) | Ubungakanani (intshi) | Izinga lokugalela (kg/s) | Umthamo wokuhluza (itoni) |

| 178*178*50 | 7*7*2 | 0.2-0.6 | 5 |

| 228*228*50 | 9*9*2 | 0.3-1.0 | 10 |

| 305*305*50 | 12*12*2 | 0.8-2.5 | 15 |

| 381*381*50 | 15*15*2 | 2.2-4.5 | 25 |

| 430*430*50 | 17*17*2 | 3.0-5.5 | 35 |

| 508*508*50 | 20*20*2 | 4.0-6.5 | 45 |

| 585*585*50 | 23*23*2 | 5.0-8.6 | 60 |

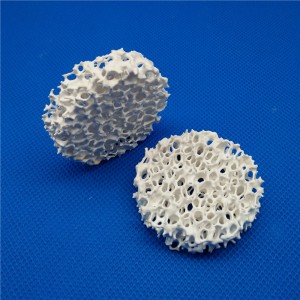

| Izinto eziphathekayo | IAlumina |

| Umbala | Mhlophe |

| Ukuxinana kwePore | 8-60ppi |

| I-Porosity | 80-90% |

| Ukuchasa | ≤1200ºC |

| Ukugoba Amandla | >0.6Mpa |

| Amandla oxinzelelo | >0.8Mpa |

| Umthamo-ubunzima | 0.3-0.45g/cm3 |

| Ukuxhathisa ukothuka kwe-Thermal | 6 amaxesha/1100ºC |

| Isicelo | I-aluminiyam, i-alloys ye-Aluminiyam kunye nezinye i-non-ferrous alloys |

1. Ukucoca ulwelo lwesinyithi olunyibilikayo

2. Inkqubo yokungena eyenziwe lula

3. Ukuphucula isakhiwo se-metallurgical of castings

4. Nciphisa ukungahambelani nokusaswa

5. Ukuphucula umgangatho wokuphosa

6. Ukunciphisa ukuphosa iziphene ze-oxidation yangaphakathi

7. Nciphisa iziphene zomhlaba emva kokulungiswa kwee-castings

1.Ukwenyuka koLwando

Ukususwa kwe-inclusions kwenza isinyithi simanzi ngakumbi, okukhokelela ekuzaliseni ukubumba okulula, ukwakhiwa kwesakhiwo esingcono, kunye nokuchithwa kwecandelo elibhityileyo.

2.Ukunciphisa uMngundo kunye neDie Wear

Ukususwa kwe-inclusions kunye nezinye i-debris non-metallic kwi-melt kunciphisa i-die soldering kunye ne-mold-metal interaction, ethoba umgangatho wokubumba kunye nobomi benkonzo.

3.Ubomi besixhobo eside

I-Oxide kunye ne-intermetallic inclusions zenza "iindawo ezinzima" ezonakalisa izixhobo kwi-machining kunye nokugqiba imisebenzi.Ukucoca kunciphisa ukunxiba kwesixhobo kwaye kwandisa imveliso.

4.Ukwala okumbalwa

Ukubandakanywa kwe-nucleate porosity, kudala iinyembezi ezishushu ngexesha lokuqiniswa, kubangela iziphene ezingaphezulu ezonakalisa imbonakalo, kwaye zihlala zinciphisa iimpawu zoomatshini.Kwiimeko ezininzi, ukucuthwa kohluzo kwaliwe ukusuka kwizizathu ezinjalo ukuya kwi-zero.Ukuphuculwa kwesivuno ukuya kufutshane ne-100% kunye nokuncitshiswa kwemilinganiselo yokwaliwa ukuya okanye kufutshane ne-0% kuqhelekileyo.

1. Ukugalelwa kwesanti

2. Ukwenziwa kweqokobhe

3. Uxinzelelo oluphantsi lokuphosa ukufa

4. Ukwenziwa kokungunda okusisigxina

5. Iinkqubo zokubamba kunye nokudlulisa